Explanation:

When an exhaust manifold gasket is leaking, it can cause a puffing noise from the engine compartment due to the escaping exhaust gases.

Explanation:

If the high-pressure fuel gauge shows 375 psi, it suggests that the high-pressure regulator is functioning properly, as it's maintaining pressure within the expected range. Therefore, the correct answer is: defective high-pressure regulator.

Explanation:

The mixer in a compressed natural gas (CNG) engine blends air and gas before entering the intake manifold of the engine. This mixture is essential for proper combustion within the engine.

Explanation:

Vehicles equipped with Compressed Natural Gas (CNG) systems are often marked by an NGV (Natural Gas Vehicle) sign. This sign helps easily identify vehicles that use natural gas as fuel.

Explanation:

The NGV engine regulator is responsible for regulating the pressure of natural gas from the tank before it enters the engine. This ensures that the gas is delivered at the appropriate pressure for efficient combustion in the engine.

Explanation:

When an EPA-certified CNG system fails due to a high-cost component, the first step should be to check with the system manufacturer for warranty coverage. This ensures that the repair is conducted according to manufacturer specifications and may provide cost-saving options for the customer.

Explanation:

Non-ammonia soap is commonly used to check fuel line connections after a compressed natural gas conversion because it can help detect leaks by producing bubbles when applied to the connections. Nitrogen, propane, and carbon dioxide are not typically used for this purpose.

Advertisement

Explanation:

If the manual lock-down valves are not opened properly after installing a new CNG fuel tank, it can prevent the vehicle from accepting fuel.

Explanation:

Remove the cylinder from service. Stress corrosion cracking poses a significant safety risk, so it's essential to take immediate action to prevent any potential hazards.

Explanation:

While the other options could potentially cause a no-start condition, recurved timing typically wouldn't directly lead to such an issue. Timing adjustment usually affects engine performance but doesn't directly prevent the engine from starting.

Explanation:

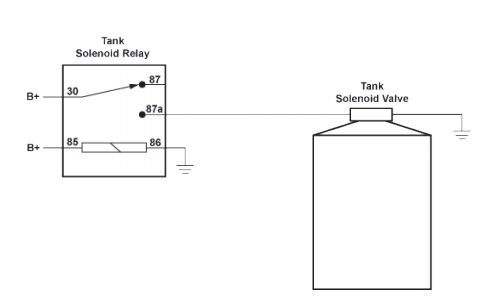

Remove the relay and install a jumper wire across terminals 30 and 87 to allow the cylinder to be vented.