Correct answer: Oil leak

You would notice an oil leak with a damaged transmission case. It’s also a possible symptom of a damaged rear extension housing mating surface or center adapter plate. The other things wouldn’t occur as a result of these damaged parts.

Correct answer: worn driveshaft slip joint splines.

Slip joint spline wear is uncommon and unlikely to cause noticeable vibration.

Correct answer: Both X and Y

Both technicians are correct.

Correct answer: Y only

Technician Y is correct. A broken tooth on the counter (cluster) gear could be the cause of the clunking or knocking noise.

Correct answer: Maladjusted, loose or worn shift linkage

If the shift linkage is loose, maladjusted or worn, you might notice the transaxle jump out of gear. Broken or worn synchronizers and having a clutch that needs adjustment will lead to hard shifting. If the cover springs are weak, that would lead to noise while in reverse.

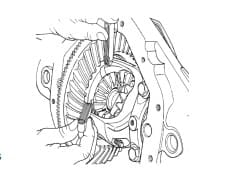

Correct answer: the clutch disc must be aligned with an aligning tool before transmission installation.

If the clutch disc is not aligned, the transmission input shaft can be damaged and/or the transmission will not be properly aligned.

Correct answer: Front bearing retainer (quill)

The front bearing retainer component cannot be removed from a transmission/transaxle before removing it from the vehicle.

Advertisement

Correct answer: Both X and Y

Both technicians are coorect. A loose differential case pinion shaft could be the cause and also worn CV joints.

Correct answer: Both technicians

Both of these technicians are correct. The snap rings do have a selective fit. They also should be appropriately placed so that the pliers can grab hold of them for replacement.

Correct answer: X only

Technician X is correct because u-joints must be in phase to avoid vibration because they will not cancel each other out. Technician Y is wrong because they must be in alignment or a vibration will result.

Correct answer: Y only

Technician Y is correct because the clutch being out of adjustment will cause shifting problems particularly in the lower range gears. Technician X is wrong because a defective blocking ring generally does not cause shifting problems into first gear.

Correct answer: Both technicians

Both technicians are correct. The faulty inboard trunnion leads to a thunking noise while traveling in a straight line during acceleration and deceleration. In addition, a faulty outboard CV joint leads to a loud clacking sound while cornering. It’s also possible to hear a winding or clicking sound while moving forward.

Correct answer: Both X and Y

Both technicians are right.

Correct answer: Both X and Y

Both technician are right. A failed front axle shaft CV joint and a different front and rear tire diameters could be the cause of the problem.

Advertisement

Correct answer: Toe contact with both convex and concave sides

If the pinion contains the right depth with too light clearance between the ring gear and pinion, there will be incorrect contact between the two. The ring gear tooth pattern shows toe contact on both the convex and concave sides. There would be no other type of ring gear to pinion contact.

Correct answer: Both X and Y

Both technicians are correct.

Correct answer: Side gear clearance

The correct answer is side gear clearance.

Correct answer: Remove shims from the right side and add shims to the left

You want to remove shims from the right and then add the equal amount to the left side. This moves the ring gear inward. It also decreases the backlash without altering preload.

Correct answer: Y only

Technician Y is correct because rear wheel bearing noise is heard while cornering. Technician X is wrong because a preload problem would be heard going straight not cornering.